“Even though it might be less than an hour, time in the shop is money.”

Matt Cole-News Editor, Commercial Carrier Journal

.png)

More uptime means more profits.

Frequent drain intervals are costing you.

Using the same oil types and maintenance intervals for all your equipment may seem like a cost-saving strategy at first. But the truth is, it usually costs you more. When it comes to proactive maintenance and improving the reliability of your fleet, your choice of oil makes a difference.

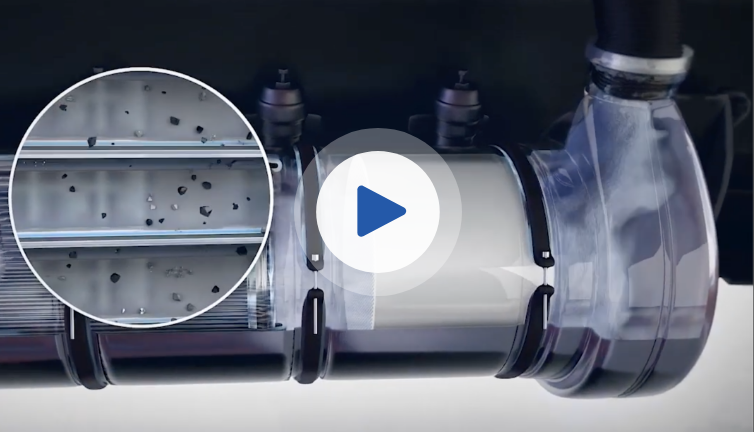

See how advanced formulations outsmart contaminants to protect

your engines longer.

Proven protection that lets you extend oil drain intervals and keep

equipment on the job longer to give you a competitive advantage.

Oil and DPF service intervals

at-a-glance

Knowing the OEM recommended service intervals for your equipment lets you plan maintenance effectively to avoid unnecessary downtime and extra costs.

YOUTUBE

Ozark Trucking: Engine oil testing can extend drain intervals and save money

Extending drain intervals can give you the competitive edge

Choosing an oil with protection that lets you reduce the number of annual drains keeps equipment on the job.

Real Business Owners. Real Results.

“By the time you pay for the labor and the downtime to have the oil changed more often, it’s often more cost effective to go with a longer oil change interval and still maintain the oil viscosity and wear limits.”

“With Delo 400 ZFA 10W-30, after 75,000 miles, the oil samples come back in really good condition.”

“We’re pushing out our oil drain intervals because the wear rate is unbelievable, and that means cost savings and confidence in reliability.”