Explore the ways oil can

save you money:

" We've been watching our oil samples and we've been able to extend some of our oil drain intervals. Even some of our heavier used yellow iron, some of that stuff we run at 200 hours to 400 hours.

Mike Kerfeld, Fleet Manager, Landwehr Construction

Construction Equipment Products

Where to buy Chevron Lubricants

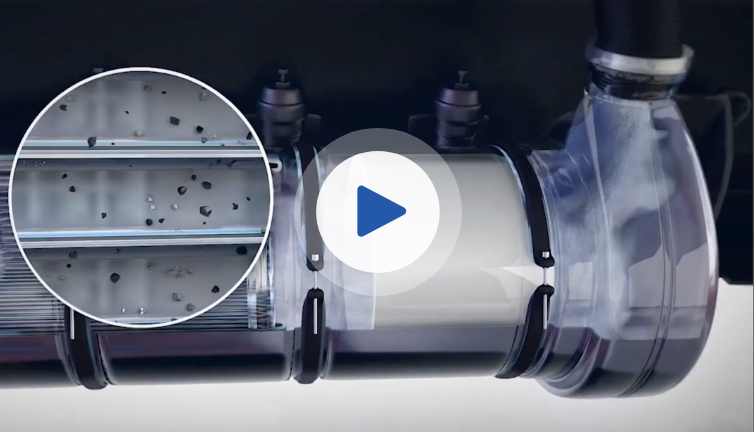

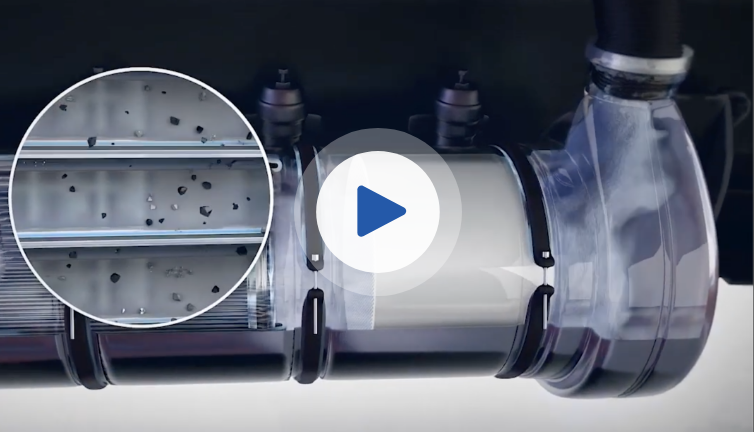

Extending drain intervals can give you the competitive edge

Choosing an oil with protection that lets you reduce the number of annual drains keeps equipment on the job.

.png)