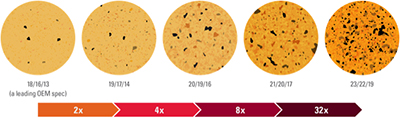

Many new oils contain up to 32 times more contamination than

OEMs recommend. Added maintenance-induced contamination

from a dirty work environment compounds the problem. As more

contaminants get into the fluid, it creates a snowball effect,

accelerating wear and tear.

Contamination can reduce component life 2x to 4x

and cost millions of dollars a year.

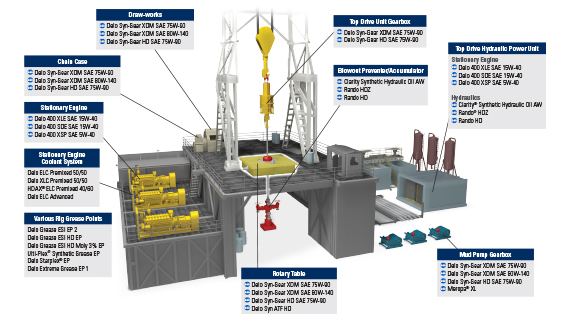

Speak to a rep and see how we can help reduce unscheduled shutdowns to improve production, meet performance, viscosity and cleanliness specifications and consult on any gaps identified.

Why do machines require clean lubricants?

There’s a reason equipment manufacturers set precise oil cleanliness requirements. Find out just how little it takes to contaminate clean oil and how much of an impact it can have on your productivity and component life.

Why do machines require clean lubricants?

Use our free, easy tool to estimate possible equipment damage by comparing your current oil cleanliness to the level required to maximize equipment component life.

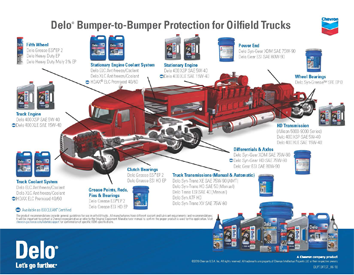

Inside out Protection

Delo® heavy-duty engine oils, gear oils and coolants are formulated to extend the life of equipment and provide you with inside out protection.

.jpg)