ISOCLEAN® Certified Lubricants Program

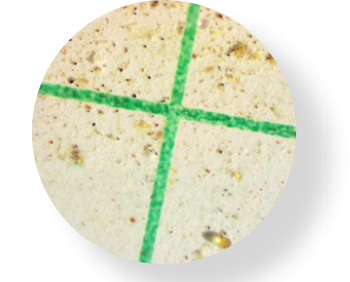

Did you know that particle contamination is a major cause of equipment failures? Ensure your lubricants meet OEM cleanliness requirements to help minimize downtime, reduce maintenance costs, and extend equipment life using the ISOCLEAN® Certified Lubricants Program.

Clean Oil Videos

Calculate your cleanlliness

In three easy steps, calculate your current ISO cleanliness level and see how it may be impacting your equipment life.

Real results

Typical oil vs Clean oil: Does it matter?

Short answer, yes it does. Watch our Proof of Performance video series to see why starting with certified clean Chevron ISOCLEAN® Lubricants can help you avoid costly equipment downtime, unplanned service costs and unexpected repairs.

A better way to maintain your equipment

Typical oil vs Clean oil: Does it matter?

Typical new oil could be damaging your equipment

The benefits of switching to certified clean oil

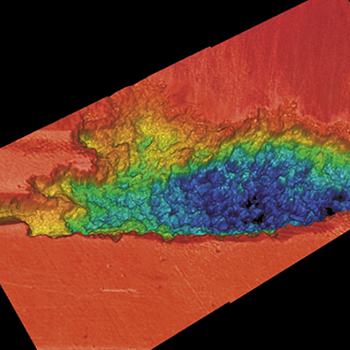

What really breaks down when there's contamination?

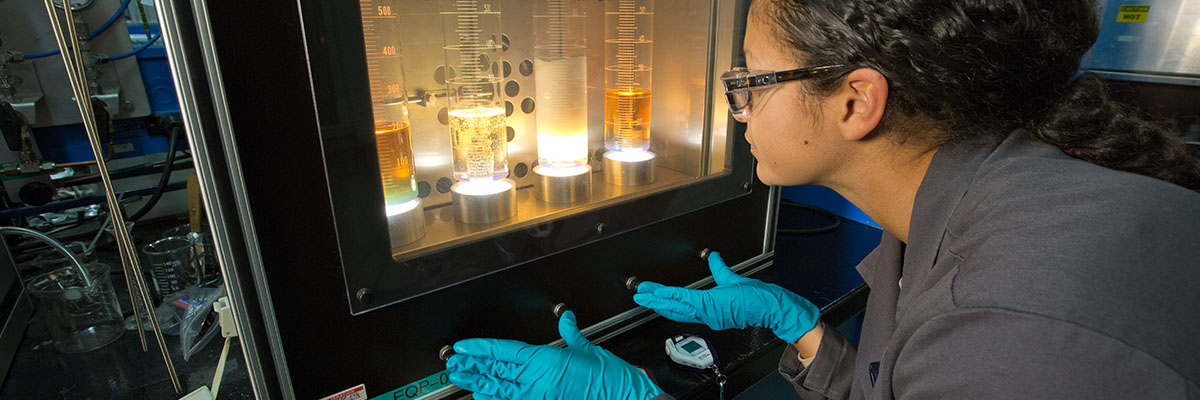

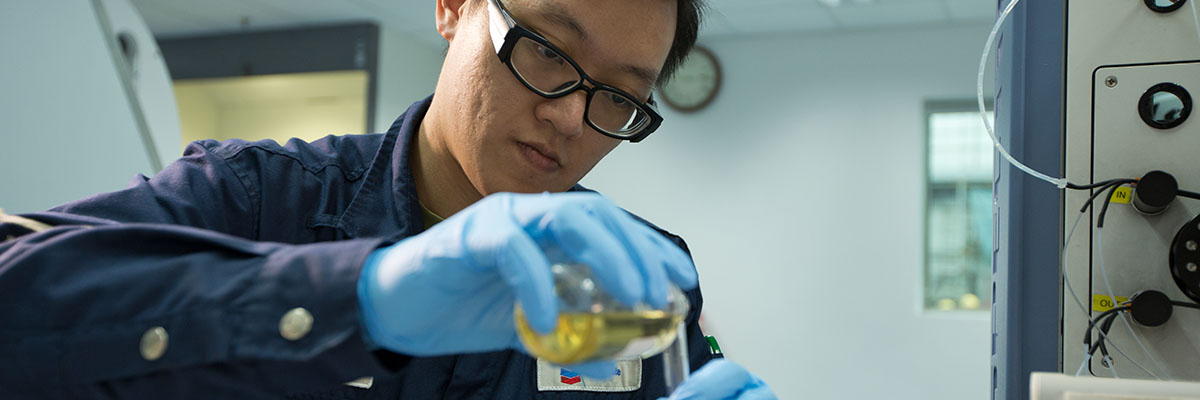

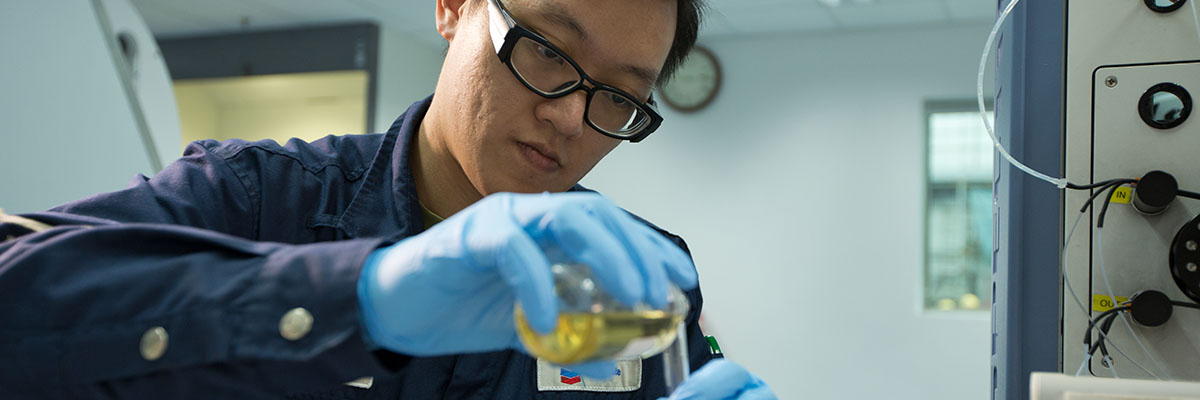

Every delivery of ISOCLEAN® Certified lubricants has been lab-tested using a state of the art process, is certified, and is backed by the Chevron brand.

Implementation and switchover is quick and easy - our ISOCLEAN® Certified lubricants sales representatives will help get you started.

ISOCLEAN® Certified lubricants are designed to meet critical OEM fluid cleanliness requirements, allowing users to maximize equipment life.

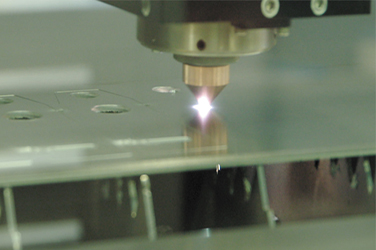

ISOCLEAN® Filtration

Stop wear and protect your equipment. Particle contamination is the #1 cause of lubricant-related equipment failure. Hear how ISOCLEAN® Certified Lubricants helped improve the equipment life and reliability of our customers' equipment.

Construction company increases equipment uptime

Waste Hauler company doubles the life of their oil

"… sticking valves and leaking seals were costing us over $12,000 each year in pump cylinder and valve body costs. With ISOCLEAN® Certified Rando HD 68 in midstream, one pump's life was almost doubled."

Why ISOCLEAN® Certified Lubricants?

It's estimated that 82% of equipment failure is particle-induced. Read how our customers are maximizing uptime with ISOCLEAN® Certified lubricants.

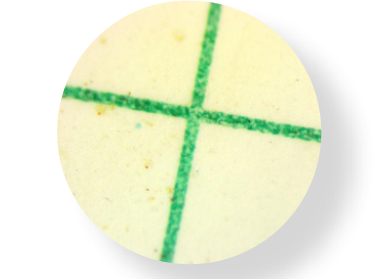

Certified clean

It's what you can't see that's most harmful. These helpful guides will show you how ISOCLEAN® Certified Lubricants can help you to control particle contamination and meet the OEM oil cleanliness specifications for your equipment.