Does a Change of Season Mean a Change of Greases?

A few considerations

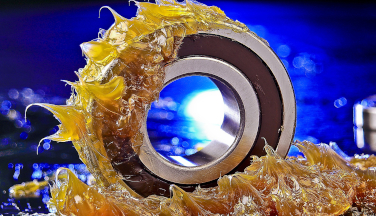

Grease is the unsung hero of heavy-duty equipment maintenance, quietly doing its job but often taken for granted. But maintenance professionals understand the nuances between different types and grades of grease, and that the choice of a grease can have a consequential impact on equipment operations.

The chief distinction among greases is the National Lubrication Grease Institute (NLGI) rating, a measure of the hardness of a grease. The higher the rating, the harder the grease. The number is determined by the standard ASTM D217 “cone penetration of lubricating grease” test. There is really no difference in the type or quality of the oil in an NLGI 1 or 2 grease. The difference is in the amount of thickener, the additive that defines the grease’s consistency. Higher levels of thickener relative to the oil will generally produce a thicker or harder grease and raise the NLGI rating.

NLGI 2 is the most commonly used, general-purpose grade for typical heavy duty on- and off-road and industrial applications. Grade 2 greases offer the thickness and stability needed for heavy loads and high operating temperatures, particularly for applications such as wheel bearings or bushing pins that require a grease to stay in place.

However, as winter brings colder weather across much of the country, many operators switch to a NLGI 1 grease, which pumps and flows more easily at low temperatures. An NLGI 2 grease that is too stiff may not perform reliably at start-up in extreme cold, leading to insufficient lubrication and potential component wear. A softer grease will reach all necessary lubrication points quickly and efficiently, providing more complete coverage of friction surfaces, while reducing the risk of hardening or even freezing in sub-zero wintry conditions.

Outdoor temperatures are not the only consideration in switching from a thicker to a more fluid grease. If you have an automated or centralized loop greasing system, particularly one with long grease lines or narrow passages, you will want a softer grease that can be pumped without overstressing the system or blocking the lines. An NLGI 1 grease is better suited for this purpose.

NLGI 2 remains the preferred solution for moderate and warmer climates, and for use with manual grease guns and direct lubrication. So, keep an eye on the thermometer and be ready to switch back when the weather changes. Just as an NLGI 1 grease flows more easily in cold weather, it may have a tendency to leak away from the areas it is meant to lubricate when the temperature turns up.

Chevron’s Rykon® calcium sulfinate grease is available in both NLGI 1 and NLGI 2 formulations, which ensures compatibility between your cold and warm weather lubrication needs. As always, check your equipment manufacturer’s recommendations before changing greases.

12/29/2025