POWER GENERATION INDUSTRY

You’re counted on to deliver

Downtime puts people in the dark

As power grids transition toward more readily available power generation options, the ability of natural gas engines to come online and provide reliable production is becoming increasingly important. Protecting these engines with a low ash oil formulated for the unique needs of your equipment will help avoid the damaging effects of corrosive acids and deposits, and reduce the depletion of lubricants to extend drain intervals — key functions that contribute to reduced maintenance costs and increased equipment reliability.

What’s the right lubricant?

Each type of gas creates a unique set of operational challenges for engines when it’s burned. As a result, it’s critical that you select an oil that has the right formulation of specialized additives—including the proper amount of ash, to combat those specific threats.

Pipeline

Pipelines are the safest and most efficient way to provide a consistent and reliable supply of natural gas to power generation operations. The primary contaminant in commercial pipeline natural gas is methane, with smaller amounts of ethane, propane and butane usually also present.

Heavy Duty Engine Oil Recommendations: HDAX 9200

Alternative: HDAX 5200

Biogas

Biogas is produced when plant and animal products (organic materials) are broken down by bacteria in an oxygen-free environment. This anaerobic digestion process turns these materials into biogas, which contains gas as well as liquid and solid soil products. Biogas itself contains large quantities of hydrogen sulfide (H2S), which classifies it as a sour gas. This contaminant can be removed with the proper method of scrubbing.

Heavy Duty Engine Oil Recommendation: HDAX 9500

Landfill

Landfill gas contains 40-60% methane and a significant

number of contaminants. It may also contain siloxanes

and other damaging compounds that originate from

waste materials used to create the gas

Heavy Duty Engine Oil Recommendation: HDAX 9500

Dual Fuel

This type of engine operates on a mixture of two different fuels, usually a combination of diesel and natural gas. Some dual fuel engines burn varying mixtures of biodiesel, bio-gas, landfill gas and others. An important advantage of dual fuel engines is their ability to seamlessly transition from one fuel to the other without interrupting power generation, should the supply be interrupted.

Heavy Duty Engine Oil Recommendation: HDAX 9700

Alternative: HDAX 5200

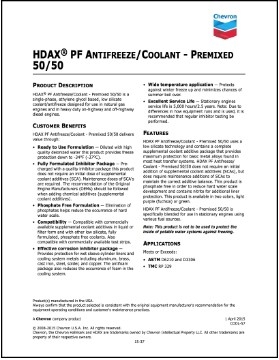

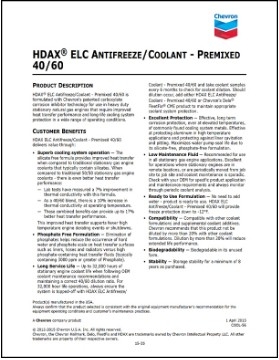

Coolants count too

Another vital component of industrial engine protection is the cooling system.

Like engine oils, coolants have become increasingly sophisticated in their chemistry in recent years. Similarly, additives designed to combat corrosion and other damaging conditions can gradually lose their ability to function over time, making regular monitoring an essential part of your regular maintenance program.

High ambient temperatures can result in unplanned engine derating due to the mechanical stresses of extreme operating conditions. By changing from a conventional 50/50 coolant mix to a 40/60 ELC formulation, you can avoid derating and lost revenue through diminished production.

Chevron offers a full line of next-gen coolants formulated to meet the specific demands of different engine types with protection that extends the life of the system. Explore below to learn more, then connect with a Chevron expert to find the one that’s ideal for your equipment.

Do you want more information? Get the product data sheets:

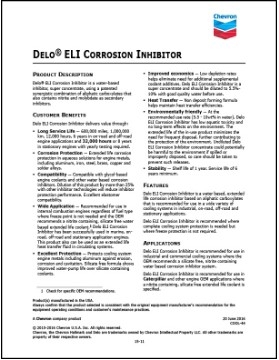

The ideal choice for warmer climates

For applications where machines don’t require anti-freeze protection, Chevron offers the Delo ELI Corrosion Inhibitor. Its patented formulation protects cooling system metals from corrosion, erosion and pitting, including aluminum, iron, steel, brass, copper and solder alloys.