.jpg)

GAS GATHERING & COMPRESSION

Two factors have the most impact on your

lubrication requirement:

Engine type

Chevron image library. CAT 3516 TALE engine at Biogas Plant.

4 Stroke

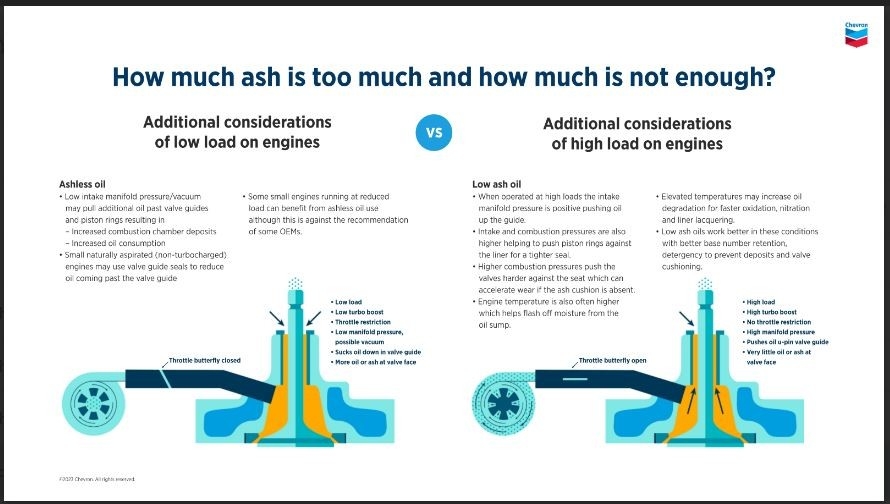

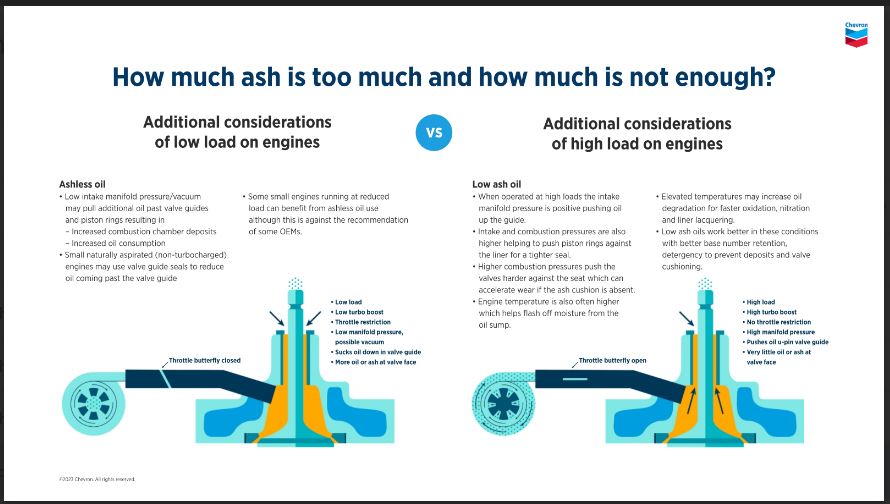

Most natural gas engines are four-stroke/four-cycle engines with intake and exhaust valves, like gasoline or diesel engines. For this equipment, it’s desirable to have a moderate amount of ash in the oil, that acts as a cushioning agent to mitigate valve recession.

Heavy Duty Engine Oil Recommendations:

Photo: Ajax Engines | New, Refurbished, Remanufactured & Rebuilt Ajax Engines | Production Engine & Pump (productionengineandpump.com)

2 Stroke

A smaller subset of operations uses two-stroke engines, which generally call for an ashless oil as even the smallest amounts of ash buildup can plug intake and exhaust ports.

Heavy Duty Engine Oil Recommendations:

Engine type

Sour

Well head gas that contains significant amounts of hydrogen sulfide (H2S) is often referred to as sour gas. This composition increases the threat of piston and cylinder liner wear along with corrosion and engine contamination.With this type of fuel, compressors can use the same oil as the engine.

Heavy Duty Engine Oil Recommendations:

Sweet

Natural gas or landfill gas is known as sweet gas, if it contains only trace amounts of H2S and CO2. In its pure form, sweet gas is non-corrosive, but may contain damaging rust particles picked up in transmission lines. With this type of fuel, compressors can use the same oil as the engine.

Heavy Duty Engine Oil Recommendations:

Wet

Liquid hydrocarbons found in “wet” natural gases cause a variety of issues, ranging from deposits in the fuel system, combustion chamber and ports to sticking fuel-valves and piston rings. If you’re using a wet natural gas, you need to use a specialized oil formulated toprotect compressors.

Heavy Duty Engine Oil Recommendations:

What about compressor lubrication?

The right oil type for the compressor is determined by the expected amount of viscosity loss that will occur after the oil enters each area of the cylinder lube system.

Factors affecting viscosity loss include gas type, engine cleanliness, pressure and operating temperature. Generally speaking, heavier hydrocarbon gases and higher discharge pressures result in more dilution of the cylinder oil, which reduces the viscosity. To avoid excessive viscosity loss, synthetic lubricants or heavier ISO grade mineral oils are recommended.

A Chevron lubricant specialist will help you choose the right oil for your application.

Coolants count too

Another vital component of industrial engine protection is the cooling system.

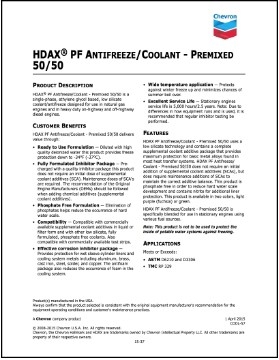

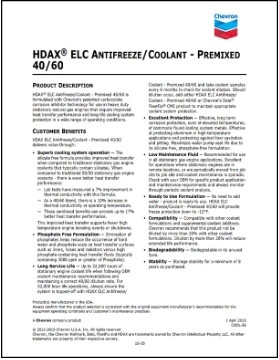

Like engine oils, coolants have become increasingly sophisticated in their chemistry in recent years. Similarly, additives designed to combat corrosion and other damaging conditions can gradually lose their ability to function over time, making regular monitoring an essential part of your regular maintenance program.

High ambient temperatures can result in unplanned engine derating due to the mechanical stresses of extreme operating conditions. By changing from a conventional 50/50 coolant mix to a 40/60 ELC formulation, you can avoid derating and lost revenue through diminished production.

Chevron offers a full line of next-gen coolants formulated to meet the specific demands of different engine types with protection that extends the life of the system. Explore below to learn more, then connect with a Chevron expert to find the one that’s ideal for your equipment.

Do you want more information? Get the product data sheets:

The ideal choice for warmer climates

For applications where machines don’t require anti-freeze protection, Chevron offers the Delo ELI Corrosion Inhibitor. Its patented formulation protects cooling system metals from corrosion, erosion and pitting, including aluminum, iron, steel, brass, copper and solder alloys.