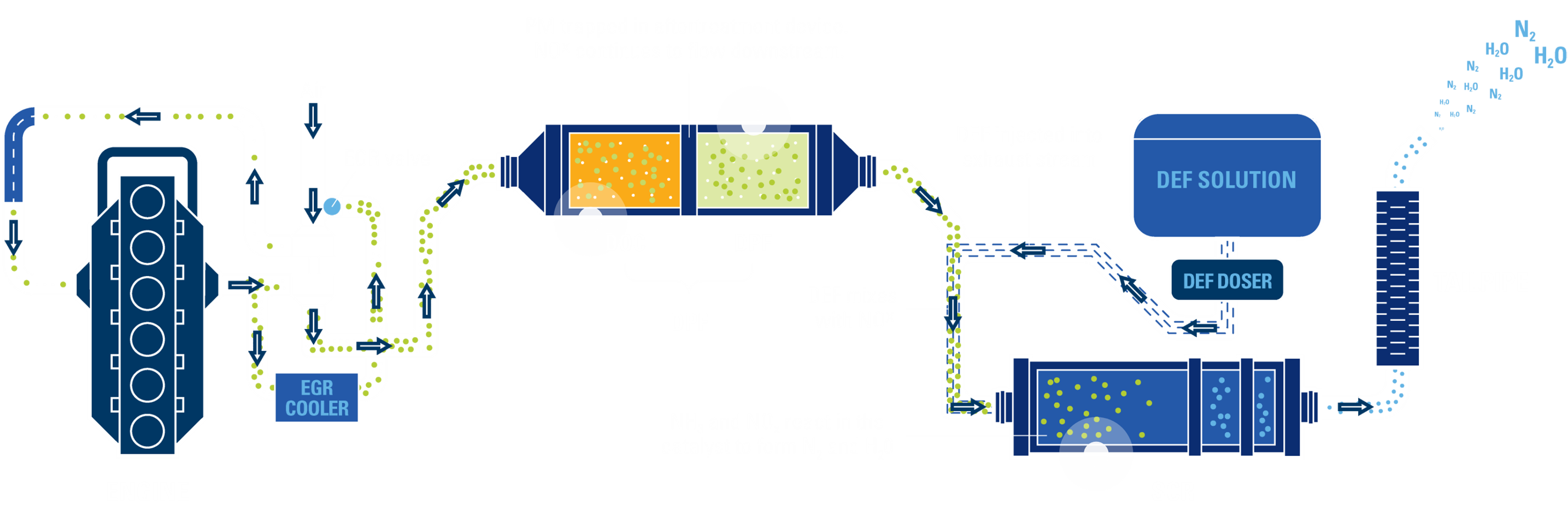

The EATS trade-off

The latest category of heavy-duty engine oils were specifically designed to protect this latest generation of engines, but oil technology has not advanced far enough when it comes to optimizing and protecting the aftertreatment system, especially with regards to the diesel particulate filter (DPF). Consequently, fleet owners and operations managers have been forced to make a trade-off—one that requires more fuel.

The DPFs downside

DPF regeneration cycles

Once enough soot and ash accumulate, the engine initiates a

process where extremely high temperatures burn off the

collected particles to regenerate the DPF. Each regen requires

incremental fuel use, decreasing fuel economy and often forcing

equipment downtime.

What's actually happening?

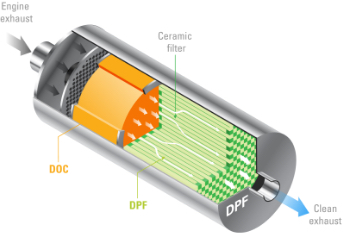

DPFs play a crucial role in cleaning diesel exhaust before it hits the tailpipe, reducing emissions of particulate matter (PM). As fuel burns, the DPF collects and stores up to 98% of incombustible particles in the form of ash and soot.

Ash clogging in the DPF

Soot burns off through regeneration, but ash remains in the DPF.

Engine lubricants contain metallic additives, such as anti-wear and

detergents, which contribute heavily to ash buildup in the DPF. Despite regen cycles, this means eventual DPF clogging, resulting in increased service intervals, unnecessary downtime or costly replacement.

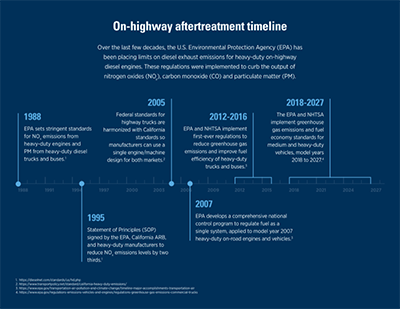

The cost of Tier 4 Final

Tier 4 Final engines are here for heavy-duty off- highway vehicles—and have been for a while now. Many fleets are already operating with 25% Tier 4 Final equipment. And that number is only going to grow. But there has been a resistance to embracing this technology due to associated costs. Learn more about how ash clogging in the DPF could be costing you.

The DPF impact on

fuel economy

Take a deeper dive on how fuel efficiency is

negatively impacted by oil contaminant clogging

in DPFs.

Diesel Particulate Filter Operation

Learn how the DPF works, and what effect it has on fuel economy.

Cleaner air and lower-ash

lubricants

See how landmark legislation on air quality has

had a far-reaching impact on diesel engine

design, producing a need for lower-ash oils.

Maintenance issues and

aftertreatment systems

Understand the causes related to ash clogging in

your DPFs and why you may be servicing them

more than OEM guidelines suggest.

Clogged DPFs and the “Fuel

Penalty”

Is your engine burning fuel at a faster rate? It

may be because ash is clogging your DPF,

causing backpressure and forced regenerations.

Modal Component - Modals Configured