The cost of

ash from oil

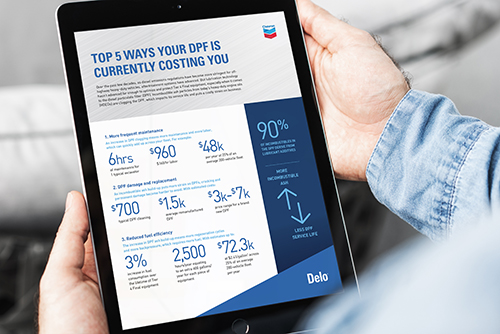

Despite the positive effects of reducing harmful emissions with Tier 4 Final equipment, adoption can mean incurring new and often hefty costs for businesses. Incombustible metallic oil additives from today’s engine lubricants are contributing heavily to ash clogging in the DPF—and businesses are paying the price.

Top 5 ways your

DPF is currently

costing you

From reduced fuel efficiency to more maintenance to increased downtime,

chances are your clogged DPF is costing

you in more ways than one.

Today’s 1% low-ash oils aren’t low enough

Oil specifications have changed over time to keep up with lower-emissions demands but have not specifically addressed improving the performance of aftertreatment systems. The percentage of ash-forming metallic additives in oils was limited to a maximum of 1% with the introduction of API CJ-4 specs in 2006, and this maximum has remained at 1% under the API CK-4 standard, introduced in 2016. Unfortunately, it’s still not low enough to maximize the lifespan of the DPF, meaning the technological advancement of aftertreatment systems has outpaced today’s lubricants. Until now.

An innovation in lubrication

technology is here

Discover the engine oil designed to combat DPF clogging, protect

your engine and your aftertreatment system.

Modal Component - Modals Configured